A new

company, Novaltek Endüstriyel Hizmetler Ltd. has

been established in order to handle following

technical field services:

1. Installation, start up and commissioning,

2. Dismantling, modification, revamping of existing

plants,

3. New

automation design, modifications and

manufacturing including hardware and

software studies,

4. Asistance for development of production

processes,

5. R&D

project configuration to develop and introduce

new products,

6. Technology transfer,

7. Training at site,

8. Market research,

9.Valuation and due diligence studies.

August 2005 - Novaltek Engineering has chosen Achenbach Gmbh.

of Germany as state of the art aluminum mill

supplier for Tekniks Corlu plant. Rolling mill

is 2500 mm wide and has about 120,000 Tons of

annual production with 0.30 x 1650 mm average

finish coils. With its automation system on

gauge, flatness, drive, handling systems and

unique 2500 mm incoming material width, this

mill will be the biggest and most modern mill in

Turkey and one of the few in Europe.

August 2005 - Civil works for earth preparation and

foundation of Corlu Aluminum Plant has been

started at site. Upper level building from the

floor will be steel structure and lower basins

and all floors will be mostly reinforced

concrete. During the design study of plant

building and infra structure very special

measures have been taken for earthquake

resistance of entire plant.

August 2005

July 2005 - An intense training period involving

continuous operation procedures has been started

for Tekniks cast house operators at Avcilar

Plant.

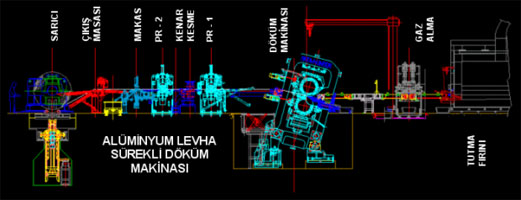

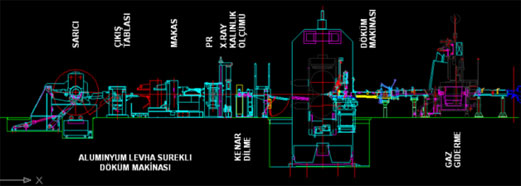

June 2005 - Novaltek Engineering has assigned Fata-Hunter

of Fin Meccanica Group as caster contractor for

Tekniks Corlu Aluminum Plant and parties have

signed contract recently. Two casters, one Super

Plus Caster 2500 mm wide and one Speed Caster

2500 mm wide will be in operation in early 2007.

June 2005 - Novaltek Engineering has received two new

orders from Teknik Aluminum A.S. First order is

for the modification of existing Avcılar

Aluminum Plant to increase capacity up to 25 %

reaching 25,000 tons of annual production within

six months. Second order is to develop

production process for all alloy qualities and

introduce new products. Implementation of these

projects has been started with two continuous

caster modifications and casting process

parameters optimization. Nowadays, after three

months of implementation, for 1xxx series alloys

1400 kg/h.m. and 3xxx, 5xxx alloys 1200 kg /h.m.

productivity figures have been already achieved

in cast-house. These figures reflect about % 20

increase for soft alloys and % 30 increase for

harder alloys. Second leg of implementation

involving coil size and reduction rate increase

will be in rolling shop. The final leg will be executed for cut to

length, slitting and tension leveling lines to

achieve better yield, strip flatness and surface

quality.

April 2005 - Another contract has been signed between

Teknik Aluminum and Novelis for one modified 3CM

Jumbo Caster 2150 mm wide which has got similar

robustness of Fata-Hunters Speed Casters. This

caster will be specifically run for automotive

and other transportation sector hard alloys

production and for part time campaign based R&D

operations. Caster will be ready for casting in

May 2006.

April 2005 - Novaltek Engineering in cooperation with

Seltek has recently introduced its first Gamma

Ray based QCS equipment for paper industry.

Serving to Cerkeskoy facility of Ucal Kagit this

device has got two sensors: one for weight, the

other for humidity of up to 3000 mm wide tissue

paper line that can run 700 m/min. With its

outstanding scanning speed up to 600 mm/s and

positional accuracy of scanning receivers and

transmitters within the super tight tolerances

of 50 cubic micrometer in space, this

equipment has been very welcomed by the wide

web manufacturers of paper, plastic and metals.

February 2005 - Novaltek Engineering has designed and

manufactured a rotary type fully automatic

plastic cap manufacturing machine (Dip Vinyl

Molding Machine ) comprising,

v Three arms rotary tool carriage,

v Tool

heating oven,

v Plastic

coating station,

v Curing

oven,

v Cooling

Section,

v Discharging

Section,

v Tool

cleaning and oiling section.

October 2004 Teknik Alüminyum, one of the leaders in aluminum

production in Turkey, has assigned Novaltek

Engineering to manage its investment and to help

build its new aluminum production facilities in

Çorlu, Turkey. Novaltek will also lead

technology design for the new factory which will

have an annual capacity of 60 thousand tons. The

partnership is likely to last for three years.

Project planning is

already underway and the new factory is expected

to be operational in 2007.

August 2004 Novaltek Engineering has moved to its new

office in Maltepe/Istanbul. |